As energy efficiency and comfort become top priorities in building design, radiant and hydronic heating systems are gaining momentum. At the core of many of these systems is a modern material: PEX, or cross-linked polyethylene. Lightweight, durable, and flexible, PEX tubing is transforming how heating systems are designed and installed—offering builders and homeowners a reliable, cost-effective solution.

What Is PEX?

PEX (cross-linked polyethylene) is a type of plastic tubing made from high-density polyethylene (HDPE), modified through cross-linking to improve its strength, flexibility, and resistance to high temperatures and pressures. It’s now widely used in heating systems to circulate hot water for space heating.

There are three types of PEX used in heating applications:

•PEX-A: Most flexible; ideal for tight bends in radiant floor layouts

•PEX-B: Slightly stiffer but widely used in residential radiant heating

•PEX-C: The most rigid, often used in above-floor panel systems

Applications of PEX in Heating Systems

1.Radiant Floor Heating

PEX tubing is embedded in concrete slabs or attached under subfloors. Hot water circulates through the tubes, radiating heat upward for even, efficient warmth. This is popular in homes, garages, basements, and commercial spaces.

2.Hydronic Baseboard Heating

PEX can be used to connect baseboard radiators to the central boiler system, offering a simpler, corrosion-resistant alternative to copper.

3.Hydronic Radiator Systems

PEX tubing also connects wall-mounted radiators to a hot water source, making retrofitting old buildings with efficient heating systems easier.

4.Snow Melting Systems

For driveways, walkways, and entryways, PEX tubing circulates warm water under outdoor surfaces to melt snow and ice automatically.

Advantages of PEX in Heating Applications

•Flexibility: PEX can bend around obstacles, simplifying installation for complex layouts like serpentine radiant zones.

•Durability: Resistant to corrosion, scale buildup, and mineral deposits, PEX ensures long-term performance with minimal maintenance.

•Freeze Resistance: While no pipe is freeze-proof, PEX can expand slightly without bursting, offering extra protection in colder climates.

•Energy Efficiency: Because of its low thermal conductivity and compatibility with low-temperature water systems, PEX supports more energy-efficient heating.

•Cost Savings: PEX requires fewer fittings, reduces labor hours, and costs less than copper or steel, making it ideal for both large commercial projects and single-family homes.

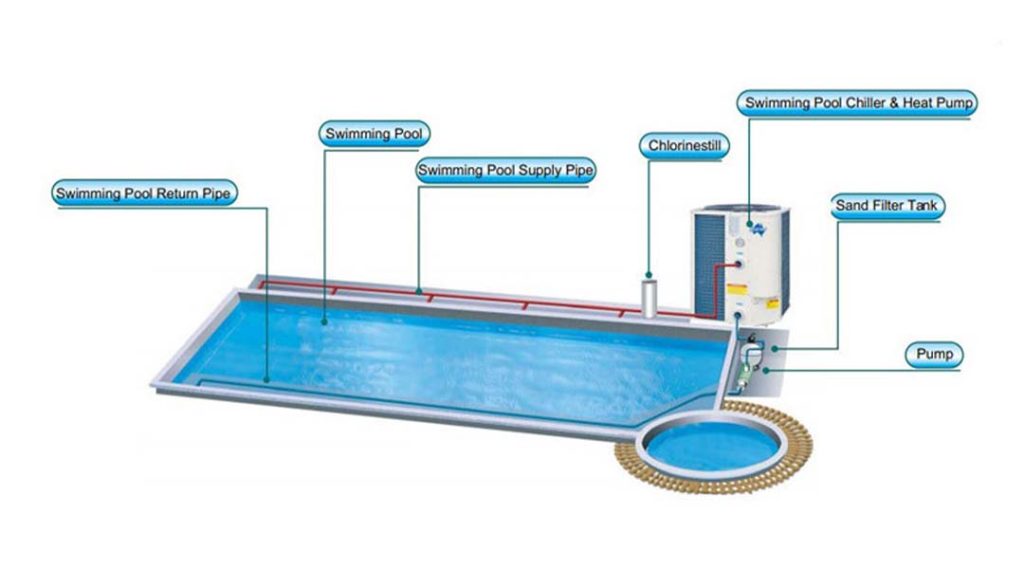

System Components Typically Used with PEX

•Boilers or water heaters to supply hot water

•Manifolds for distributing heated water to various zones

•Thermostats and zone valves for temperature control

•Insulation to prevent heat loss in slabs or walls

•Oxygen-barrier PEX (such as PEX with EVOH coating) to protect metallic components from corrosion in closed-loop systems

Best Practices for Installation

•Always use oxygen-barrier PEX in closed-loop heating to prevent rust in metal components.

•Install tubing in consistent spacing for even heat distribution (typically 6″–12″ apart).

•Secure tubing properly using clamps or staple-down systems.

•Pressure test before pouring concrete or closing floors/walls.

•Avoid UV exposure during storage and install tubing away from sharp objects or high-heat sources.

Limitations to Consider

•PEX should not be exposed to UV light, even during short-term storage.

•Rodents may chew through tubing in rare cases—always use protective barriers in crawlspaces.

•Local building codes may specify requirements for insulation, spacing, or pressure testing.

PEX systems are rapidly becoming the gold standard for hydronic and radiant heating. Their flexibility, energy efficiency, and long-term reliability make them ideal for modern heating projects—whether you’re designing an energy-efficient new home, retrofitting an older building, or installing an outdoor snow melting system. As building trends continue to prioritize performance and sustainability, PEX is poised to remain a central material in high-performance heating solutions.